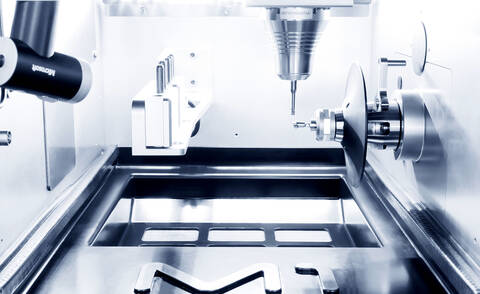

M1 Abutment Milling Unit

For processing prefabricated titanium abutments (Raw-Abutments®), glass ceramics and composite

Overview of the characteristics

- Computer-controlled milling unit with 4 axes simultaneous milling technology

- Processing of prefabricated titanium abutments (Raw-Abutments®)

- Wet processing function for glass ceramics blanks

- Milling Spindle Hard Automatic with 6 mm collet chuck

- Automatic tool changer function for 6 bur slots

- Air purge system for protecting guiding elements and spindle

- Short spindle paths, due to proximity of the tool magazine to the blank holder

- Particularly compact and space-saving

Processable materials with full equipment

Equipment upon delivery

- Grindbox Basic

- Set Tool Magazine D6

- Zero-point stylus D6

- Tool Organiser

- Raw-Abutment® fixing kit

- Calibration block M1 Abutment

- Cooling Lubricant Milling (1 l)

- Orbit Cleaning Liquid (100 ml)

- Zirkonzahn.Fräsen software

Accessories

Tool Organiser

Content: 1 piece

The Tool Organiser guarantees safe storage of up to 50 milling burs. The interaction with the milling software allows a simple and clear management of the different milling burs.

product number: ZBAC4331

Tool Organiser

Content: 1 piece

The Tool Organiser guarantees safe storage of up to 50 milling burs. The interaction with the milling software allows a simple and clear management of the different milling burs.

product number: ZBAC4331

Zero-point stylus D6 for the milling units of the M1/M2/M2 Dual/M4/M6 line

Content: 1 piece For readjusting the zero-position in milling units of the M1/M2/M2 Dual/M4/M6 line.

product number: ZBAC0731

Cooling Lubricant Milling (1 l)

Water-mixable coolant for wet processing

product number: ZBAC2118

Orbit Cleaning Liquid 100 ml

Content: 1 piece

Corrosive, acid, inorganic liquid for cleaning of the orbit

product number: ZBAC2161

Technical data

| Weight | 105 kg | |

| Width | 47.7 cm | |

| Height | 69 cm | |

| Depth | 63 cm | |

| Casing | Hardened Security Glass ISO 12150 | |

| Processing axes | 4 | |

| Electrical power | 600 W (without aspiration system) | |

| Operating voltage | 100 – 240 V | |

| Power input | 2.6 A (5.5 A) | |

| Collet chuck | Ø 6 mm | |

| Spindle speed | Depending on equipment | |

| Torque | 13 Ncm | |

Fräsgerät M1 Wet Heavy Metal

Mit vierfach-gelagertem Orbit und der integrierten Nassbearbeitungsfunktion ist das Fräsgerät M1 Wet Heavy Metal auch bestens für das Fräsen von harten Metallen wie Titan gerüstet.

scroll down to load more